Additives

AEROSIL (PYROGENIC SILICON DIOXIDE)

Aerosil is a highly dispersed, highly active, amorphous, pyrogenic silicon dioxide (SiO2) obtained by flame hydrolysis of high purity silicon tetrachloride (SiCl4).

Aerosil is fire- and explosion-proof, does not have a general toxic effect. It is a very pure amorphous non-porous silicon dioxide with a particle size of 5 to 40 nm. It is an extremely light white powder, which in a thin layer appears translucent, bluish.

Properties:

It is used as a dispersant to stabilize suspensions. It is possible to achieve thickening of the liquid with the addition of Aerosil. A mixture of aerosil with resin can be used as a high density filler and filler.

The introduction of aerosil avoids stratification and settling of various components of mixtures. The use of aerosil improves the dielectric properties, increases the resistance of mixtures to temperature extremes. Gives a thickening effect.

ALUMINUM HYDROXIDE

Aluminum trihydrate (ATH) or aluminum hydroxide is a white filler used as a fire retardant in the manufacture of artificial stone. Gives products high physical and mechanical parameters, fire resistance and low smoke generation.

It is used in the manufacture of various products based on polyester, epoxy or acrylic resins, PVC, cellulose materials and other elastomeric compounds.

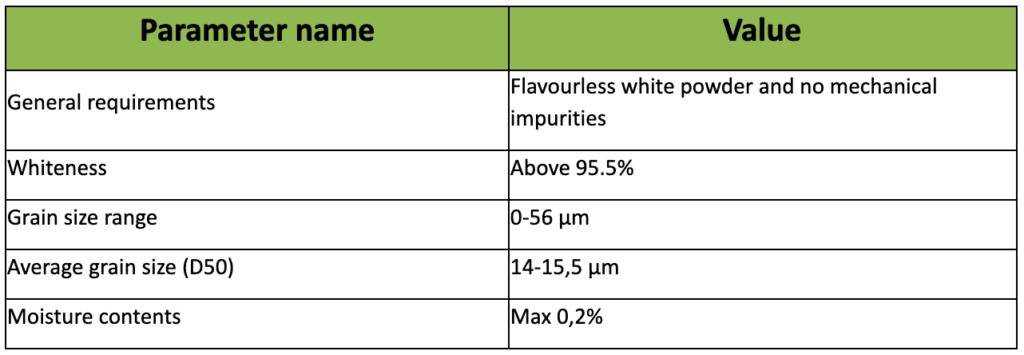

Specifications aluminum hydroxide ALFRIMAL 447 S

TITANIUM DIOXIDE

Titanium dioxide is a white substance with a melting point of 1870 ° C, insoluble in water and acids. When heated, it turns yellow, which disappears after cooling.

Basic properties of titanium dioxide:

- high whitening ability;

- good compatibility with any film former;

- good covering ability;

- high weather and moisture resistance;

- non-toxicity;

- chemical resistance.

Main areas of application for titanium dioxide:

- production of paints and varnishes;

- production of plastics;

- production of rubber products (RTI);

- paper production;

- production of chemical fibers and others.

CALCITE

Calcite Nigtas – marble chips, made in Turkey, high whiteness – 99.2%.

Due to its physical and chemical properties and structural features, NIGTAS calcite has a number of qualities that distinguish it favorably from other types of fillers:

- increased content of calcite (more than 99.5%);

- high whiteness;

- Brightness;

- good optical properties;

- increased grain strength;

- low porosity and water absorption;

- low content of coloring oxides of iron, manganese, titanium, cobalt and, as a result, high whiteness;

- low content of water-soluble salts;

- high resistance to ultraviolet radiation;

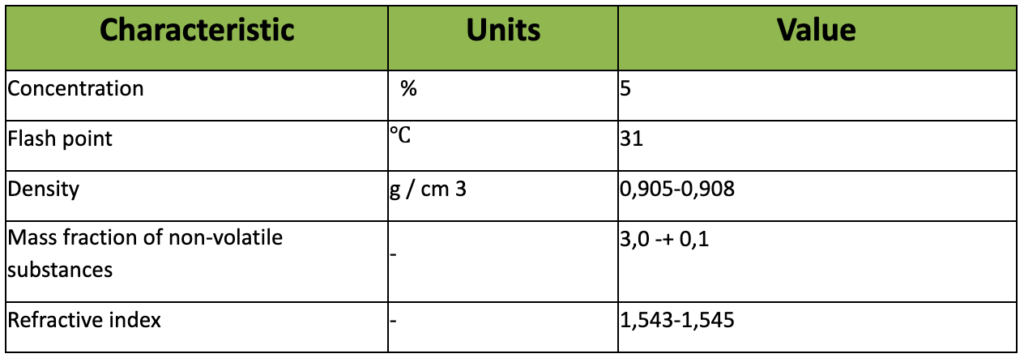

PARAFFIN IN STYRENE

Paraffin wax in styrene is intended for use as a top layer, to eliminate residual stickiness and reduce styrene emissions in the production of fiberglass and polymer concrete.

Paraffin in styrene is a whitish liquid. It is used to obtain a dry and non-sticky surface of products. When using paraffin in styrene, it is possible to obtain a topcoat from the gelcoat. Added to gelcoat 2-5% solution.

When processing unsaturated polyester materials, the product often has a sticky surface. This effect does not disappear even after a long period of keeping the product in a warm room. This is due to the effect of oxygen inhibition and evaporation of styrene from the surface layer of the cured resin or gelcoat. The addition of a small amount of paraffin solution eliminates this effect and obtains a dry, non-sticky surface.

Storage conditions

- store in a tightly closed container, in a dry, ventilated, darkened room at temperatures up to 25 ° C;

- at storage temperatures below 25 ° C, turbidity and the appearance of flakes are possible, which disappear when heated to 30-40 ° C;

- when adding paraffin, the mixture must be thoroughly mixed.