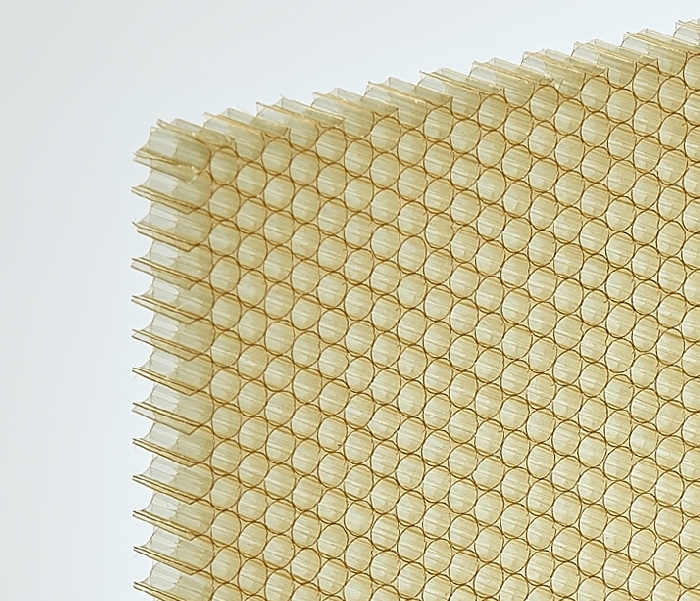

Honeycomb fillers

Honeycomb cores are made by expanding and corrugating composite materials such as fiberglass (also known as fiberglass), metal (usually aluminum), polypropylene, plywood.

Properties

In combination with two layers, the sandwich panel is characterized as a highly durable material with light weight. Thanks to the efficient hexagonal shape, the compressive strength of the honeycomb core is higher than that of the foam layers. Polypropylene filler has a number of advantages over paper filler. Such panels have excellent resistance to water, as well as to most acids, alkalis and salts, and have a low (0.065 W / mK) thermal conductivity. Protection of honeycomb panels from the effects of fire and ultraviolet radiation is ensured through the correct choice of facing materials.

Application

Honeycomb materials are widely used on both flat and curved surfaces. Applications: aerospace, light industrial composite materials, furniture, shipbuilding, automotive, recyclable containers, packaging, etc.

Types of honeycomb fillers

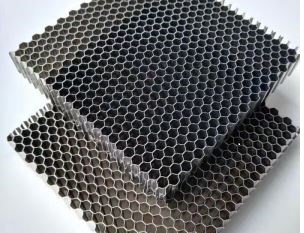

Aluminum honeycomb fillers

The construction material is made of aluminum foils.

Application:

- aviation (floor panels, interior panels, spoilers, trim tabs, servo compensators, ailerons, landing gear and cargo doors, nose cones, tail wing panels)

- rocket and space technology

- transport (rail, road, shipbuilding)

- building

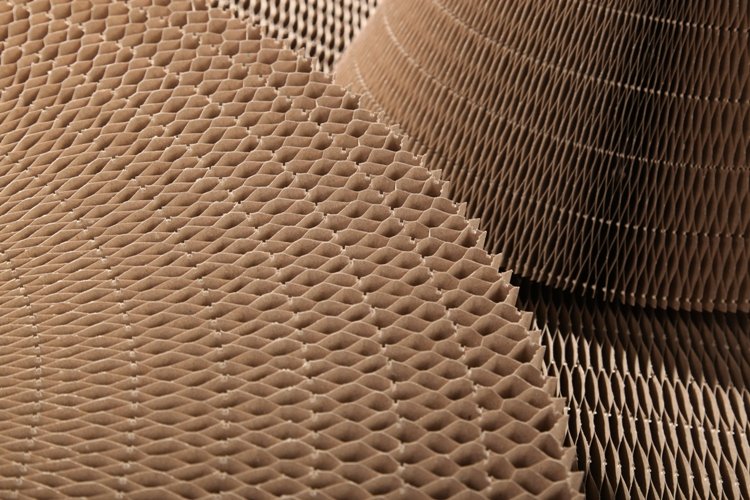

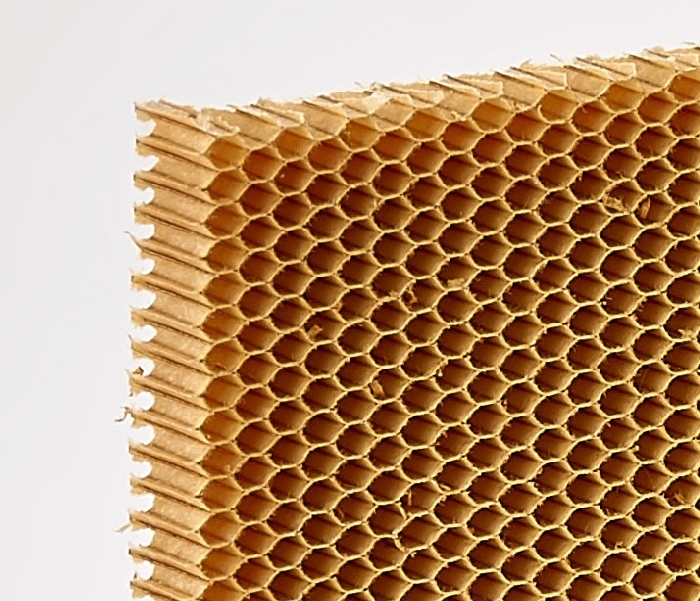

Paper honeycomb filler

It is a worthy replacement for packaging materials, which has established itself as a quality material that provides protection against scratches, shock, vibration, crushing, and the honeycomb core completely absorbs the impact energy.

Application:

- packing material

- honeycomb filling of interior doors

- creation of flat furniture panels

Polypropylene honeycomb filler

Polypropylene honeycomb is a semi-finished product used for the production of lightweight composite sandwich panels, with stability, low weight and corrosion resistance. According to the subsequent application, the materials can be in the form of open honeycomb, a sandwich of a material with a veil, or with a veil and plastic film.

Application:

- in the automotive industry (interior fittings, rear shelves, roof liners, soundproofing casings)

- application in shipbuilding (boats, yachts, catamarans, interior elements)

- application in train structures (flooring, walls and door elements, sanitary areas and furniture)

- wind power applications (blades, housings)

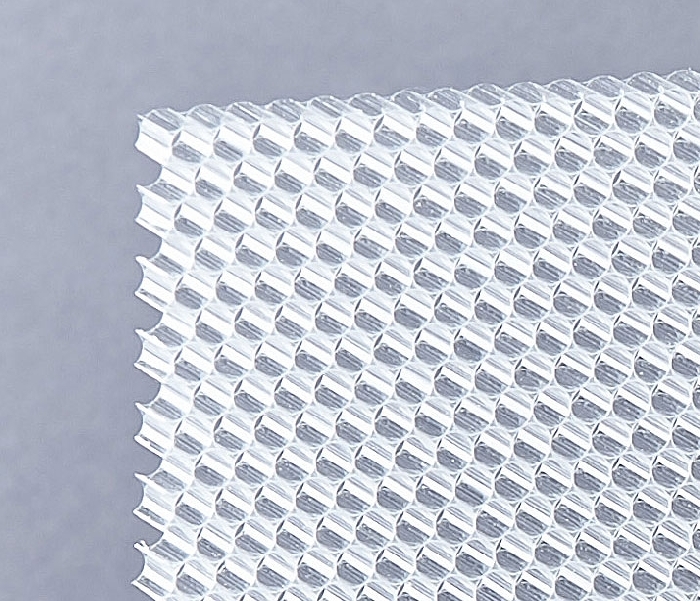

Polycarbonate honeycomb filler

It is a thermoplastic material available in various sizes, thicknesses, colors and mesh diameters. Honeycomb deflectors improve airflow efficiency, while also eliminating turbulence, pollution, moisture, noise and energy consumption.

Application

- ventilation with laminar flow

- commercial refrigeration

- climatic chambers

- wind tunnels

Aramid paper honeycomb

It is an extremely lightweight, durable non-metallic product made from aramid paper impregnated with heat-resistant phenolic resin.

Application

- in boat hulls

- in car racing bodies

- in military shelters

- in the aviation, railway and shipbuilding industries

Polyesterimide honeycomb filler

It is a thermoplastic material. This polymer differs from other thermoplastics in its high heat resistance and strength characteristics.

Application

- production of high-tech panels

- as a filler for snowboards and fairings

- production of military panels