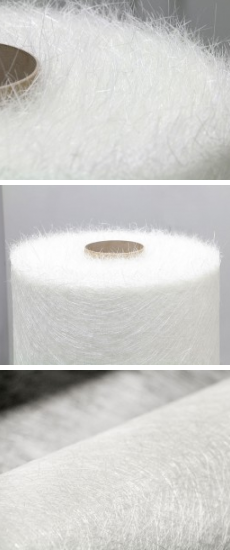

Glass mats

Emulsion glass mat with a density of 100, 150, 225 g / m2

EM glass mat with densities of 100, 150, 225 g / m2 is made from strands of chopped fiberglass connected with an emulsion binder. Emulsion glass mat has a reduced linear density (tex) and surface weight (density) compared to a standard emulsion mat. The emulsion glass mat is soft, fits well in shape, easily takes on even very complex shapes. It is characterized by medium penetration in unsaturated polyester resin and good air removal during lamination.

Application

The EM emulsion mat is suitable for the production of laminates in the contact process. Used with all types of unsaturated polyester resins for the production of glass fiber reinforced products. Suitable for making gel-coated products as reinforcement. Recommended as an outer layer of laminate in the manufacture of products with improved surface aesthetics.

Specifications

| Parameter | Values |

| Type of glass | E |

| Nominal filament diameter [μm] | 9 |

| Strand linear density [tex] | 11 |

| Nominal length of chopped strands [mm] | 50 |

| Sizing type | silane |

| Binder | emulsion |

| Standard surface weight (density) [g/m2] | 100; 150; 225 |

| Standard width [cm] | 125 |

Standard packing

| To mat with surface weight [g/m2] | 100 | 150 | 225 |

| Mat length in a roll [m] | 240 | 200 | 140 |

| Cardboard box dimensions [mm] | 1290 x 320 x 320 | 1290 x 320 x 320 | 1290 x 320 x 320 |

| Net weight of a unit package [kg] | 30 | 37 | 39 |

| Net weight of rolls on the pallet [kg] (ca.) | 450 | 555 | 585 |

| Gross weight of the load with the pallet [kg] (ca.) | 495 | 600 | 630 |

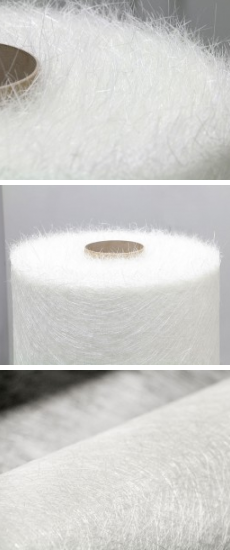

Emulsion glass mat with a density of 300, 450, 600 g / m2

EM glass mat with densities of 300, 450, 600 g / m2 is made from strands of chopped fiberglass connected with an emulsion binder. It is a soft emulsion mat that fits well in shape, saturated with unsaturated polyester resins. The product has a satisfactory ability to remove air during the lamination process. The laminate made on the basis of this emulsion mat is characterized by good mechanical properties and very good weather resistance.

Application

Emulsion glass mat is suitable for hand molding laminates. Used for the manufacture of glass fiber reinforced polyester resin products. It is used to make items of rather complex shapes. Products made with this mat are most often used:

- in shipbuilding

- in the automotive industry

- in the construction industry

- in the aviation industry

- in the electrical industry

Specifications

| Parameter | Values |

| Type of glass | E |

| Nominal filament diameter [μm] | 12 |

| Strand linear density [tex] | 25 |

| Nominal length of chopped strands [mm] | 50 |

| Sizing type | silane |

| Binder | emulsion |

| Standard surface weight (density) [g/m2] | 300; 450; 600 |

| Standard width [cm] | 125 |

Standard packing

| To mat with surface weight [g/m2] | 300 | 450 | 600 |

| Mat length in a roll [m] | 115 | 80 | 64 |

| Cardboard box dimensions [mm] | 1290 x 320 x 320 | 1290 x 320 x 320 | 1290 x 320 x 320 |

| Net weight of a unit package [kg] | 43 | 45 | 48 |

| Net weight of rolls on the pallet [kg] (ca.) | 654 | 675 | 720 |

| Gross weight of the load with the pallet [kg] (ca.) | 705 | 735 | 780 |

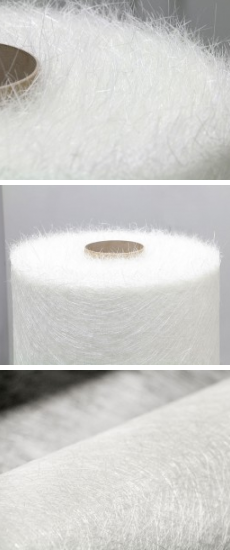

Powder glass mat 100, 150, 225 g / m2

Powdered glass mat EM with a density of 100, 150, 225 g / m2 is made from strands of chopped fiberglass connected with a powder binder. The mat has a reduced linear density (tex) and surface weight (density) compared to a standard powder mat. The EM powder mat is compact, characterized by high wetting rate in unsaturated polyester resin and good performance. The laminate made from this powder mat has high transparency and good smoothness.

Application

Powdered glass mat is most often processed in factories producing panels for the building industry, interior decoration or on a large scale in the automotive industry (interior decoration: ceiling, shelves, walls, covers, etc.).

Specifications

| Parameter | Values |

| Type of glass | E |

| Nominal filament diameter [μm] | 9 |

| Strand linear density [tex] | 11 |

| Nominal length of chopped strands [mm] | 50 |

| Sizing type | silane |

| Binder | powder |

| Standard surface weight (density) [g/m2] | 100; 150; 225 |

| Standard width [cm] | 125 |

Standard packing

| To mat with surface weight [g/m2] | 100 | 150 | 225 |

| Mat length in a roll [m] | 240 | 200 | 140 |

| Cardboard box dimensions [mm] | 1290 x 320 x 320 | 1290 x 320 x 320 | 1290 x 320 x 320 |

| Net weight of a unit package [kg] | 30 | 37 | 39 |

| Net weight of rolls on the pallet [kg] (ca.) | 450 | 555 | 585 |

| Gross weight of the load with the pallet [kg] (ca.) | 495 | 600 | 630 |

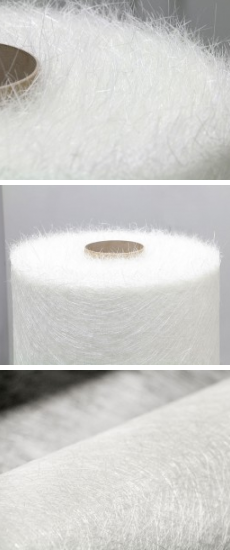

Powder glass mat 300, 450, 600 g / m2

Powdered glass mat EM is made from strands of chopped glass fibers bonded with a powder binder. The powder mat is characterized by high wetting rate in unsaturated polyester resin, stable quality and good performance. Laminate based on this mat has high transparency, good smoothness, good mechanical properties and increased resistance to weather conditions.

Application

EM powder glass mat is suitable for mechanical lamination process as well as for contact laminating. It is used for the manufacture of glass fiber reinforced products from unsaturated polyester resins. Elements can be large in size but in a simpler shape. Powdered glass mat gives high transparency and good surface smoothness. The product is mainly used in the construction industry, road construction and maintenance, and maritime transport.

Specifications

| Parameter | Values |

| Type of glass | E |

| Nominal filament diameter [μm] | 12 |

| Strand linear density [tex] | 25 |

| Nominal length of chopped strands [mm] | 50 |

| Sizing type | silane |

| Binder | powder |

| Standard surface weight (density) [g/m2] | 300; 450; 600 |

| Standard width [cm] | 125 |

Standard packing

| To mat with surface weight [g/m2] | 300 | 450 | 600 |

| Mat length in a roll [m] | 115 | 80 | 64 |

| Cardboard box dimensions [mm] | 1290 x 320 x 320 | 1290 x 320 x 320 | 1290 x 320 x 320 |

| Net weight of a unit package [kg] | 43 | 45 | 48 |

| Net weight of rolls on the pallet [kg] (ca.) | 645 | 675 | 720 |

| Gross weight of the load with the pallet [kg] (ca.) | 705 | 735 | 780 |